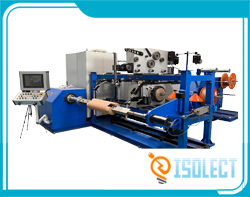

WIRE WINDING MACHINE

Our control panel software is user-friendly and designed to support different interface languages according to buyer needs.

During winding, the wire straightening unit straightens the round wire to obtain a compact winding.

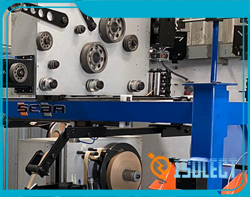

The wire braking system ensures constant wire tension for all wire ranges. In addition, the wire guidance arm positions the wire close to the winding area and ensures smooth winding.

Oval and rectangular shaped bobbins can be wound at high speed thanks to the dance system.

Strip insulation routing tool reduces the cost of winding materials and transformer by gradually increasing the insulation.

Round and flat wire openers move on a horizontal axis, follow the wire guide and feed the wire straight.

Coil winding machines are like the unsung heroes of the manufacturing world, especially when it comes to creating transformer machines. Picture this – a reliable, hardworking piece of equipment that intricately weaves copper wire with precision and care to form the heart of transformers. These machines may not be in the limelight, but their importance cannot be understated. They embody efficiency, consistency, and craftsmanship, turning raw materials into vital components that power countless devices in our everyday lives.